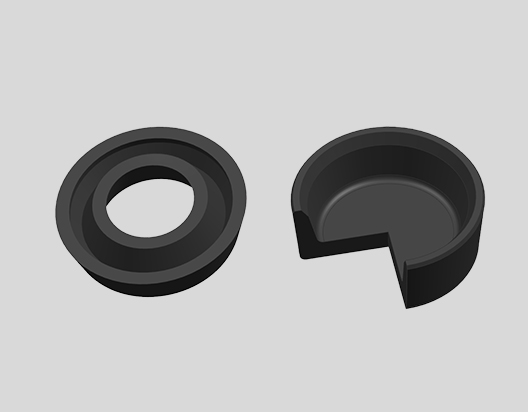

Oil seal products

Related Products

Oil seal definition and characteristics

Oil seal is the customary name for general seals, which is simply the seal of lubricating oil. It is a mechanical element used to seal grease (oil is the most common liquid substance in the transmission system), and it isolates the parts that need to be lubricated in the transmission parts from the output parts, so as not to allow the leakage of lubricating oil. The seals used for static seals and dynamic seals are called oil seals. The representative form of the oil seal is the TC oil seal, which is a double-lip oil seal with a self-tightening spring completely covered by rubber. Generally speaking, the oil seal often refers to this TC skeleton oil seal.

The function of the spring is to increase the pressing force of the sealing lip on the shaft, and it is the component required to maintain this pressing force. The spring used in the oil seal has the characteristics shown in the table below. A slight elongation can get the necessary load. At a certain elongation limit, the spring load does not change much. In addition, the spring of the oil seal should be able to function within the range of use, and the appropriate elongation should be considered for a specific length.

|

sealing medium |

spring |

||

|

|

Standard material |

special material |

|

|

|

High carbon steel wire (spring, wire) |

Stainless steel wire |

|

|

|

|

304 |

306 |

|

lubricating oil |

excellent |

excellent |

excellent |

|

water |

Difference |

excellent |

excellent |

|

water vapor |

Difference |

excellent |

excellent |

|

seawater |

Difference |

Difference |

excellent |

|

acid |

Difference |

Difference |

excellent |

|

base |

Difference |

excellent |

excellent |

The role of the metal skeleton is to maintain the matching force between the oil seal and the cavity hole, and the more important role is to keep the sealing lip in a certain position.

|

sealing medium |

metal skeleton |

||

|

Standard material |

special material |

||

|

carbon steel plate |

Stainless steel |

||

|

cold rolled steel plate |

304 |

306 |

|

|

lubricating oil |

excellent |

excellent |

excellent |

|

water |

Difference |

excellent |

excellent |

|

water vapor |

Difference |

excellent |

excellent |

|

seawater |

Difference |

Difference |

excellent |

|

acid |

Difference |

Difference |

excellent |

|

base |

Difference |

excellent |

excellent |

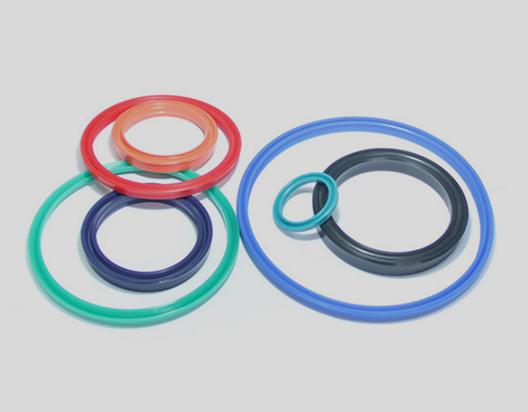

Common materials for oil seals

Commonly used materials for oil seals are: nitrile rubber, fluorine rubber, silicone rubber, acrylate rubber, polyurethane, polytetrafluoroethylene, etc.

List of Oil Seal Materials

|

name |

code |

main feature |

Operating temperature (℃) |

The main purpose |

|

Nitrile rubber |

NBR |

Excellent oil resistance, high wear resistance, good heat resistance and strong adhesion. The disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance and slightly lower elasticity. Nitrile rubber is mainly used in the manufacture of oil-resistant rubber products. |

Minimum temperature: -30℃ Maximum temperature: 100℃ |

Suitable for sealing of general hydraulic and pneumatic series |

|

Hydrogenated nitrile rubber |

HNBR |

It has good resistance to media, heat and oxidative degradation. The heat resistance is between FKM and NBR, and the wear resistance is also better than NBR. |

Minimum temperature: -30℃ Maximum temperature: 150℃ |

It is suitable for sealing of high temperature, chemicals and heat resistant hydraulic oil, and is widely used in metallurgy, electric power and other industries. |

|

fluororubber |

FKM |

Heat resistance, acid and alkali resistance and other chemicals: oil resistance (including phosphate ester series hydraulic oil) is suitable for all lubricating oil, gasoline, hydraulic oil and synthetic oil. |

Minimum temperature: -20℃ Maximum temperature: 230℃ |

It is suitable for sealing of high temperature resistance, chemicals and fire-resistant hydraulic oil, and is widely used in metallurgy, electric power and other industries. |

|

Silicone Rubber |

PMQ |

Good heat and cold resistance, small compression set, but low mechanical strength. |

Minimum temperature: -60℃ Maximum temperature: 200℃ |

Suitable for high-speed and low-friction rotary seals and food mechanical seals at high and low temperatures. |

|

Ethylene propylene rubber |

EPDM |

Good weather resistance, aging resistance in air, general oil resistance, Freon resistance and various refrigerants |

Minimum temperature: -50℃ Maximum temperature: 150℃ |

It is suitable for various automobile oil seals and various gearboxes and gearboxes, and can withstand medium and high temperature. |

|

Teflon |

PTFE |

Good chemical stability, good heat resistance, good cold resistance, oil, water, steam, chemicals and other media. High mechanical strength, high pressure resistance, good wear resistance, low friction coefficient and excellent self-lubrication. |

Minimum temperature: -200℃ Maximum temperature: 260℃ |

It is used for sealing of construction machinery and high-pressure systems. |

|

Polyurethane |

PU |

Good mechanical properties, excellent wear and oil resistance, limited working environment temperature |

Minimum temperature: -35℃ Maximum temperature: 120℃ |

Used in refrigerators and refrigeration machinery to seal |

|

Acrylate rubber |

AEM |

Good heat resistance, oil resistance, in containing The lubricating oil with sulfur, phosphorus and chlorine additives has stable performance, aging resistance, oxygen and ozone resistance, UV resistance, excellent air tightness, The function of bending deformation. |

lowest temperature: - 25°C Maximum temperature: 150°C |

It is used to manufacture oil-resistant, heat-resistant and aging-resistant products, such as seals, hoses, chemical linings, etc. |