Coal mine seals

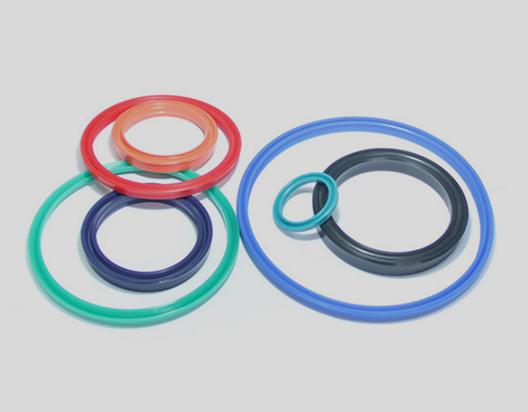

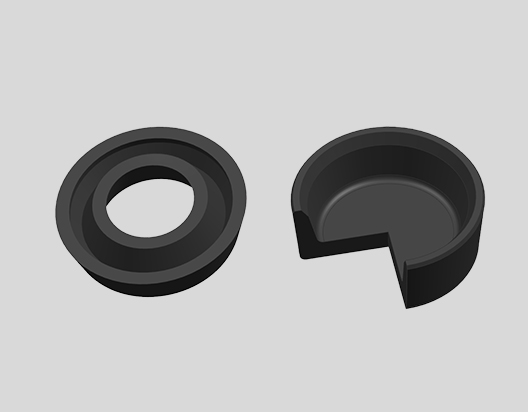

Related Products

Precautions before using seals

1. Precautions for storage

Please pay attention to the following matters when storing seals:

Do not open the package when not needed. Otherwise the seals may get "dusted" or "scratched".

Please store in a place with low humidity and avoid direct sunlight.

Ultraviolet rays and moisture accelerate the deterioration of rubber materials and dimensional changes and deterioration of resin materials.

When storing the opened product, be careful not to allow foreign matter to adhere or mix, and repackage it as it is as much as possible. Nylon, in particular, may change in size due to moisture absorption, so please keep it sealed. When moisture-proof packaging is required, please contact Shanghai Yishante Sealing Technology Co., Ltd.

Do not place near high temperature heat sources such as boilers and stoves. Rubber materials deteriorate rapidly due to heat.

Do not place near items such as motors that easily generate ozone.

Do not hang with nails, iron wires, ropes, etc., it will cause deformation of the seal or injury to the front end of the lip.

During storage, discoloration or white powder may appear on the surface (blooming phenomenon), but these conditions will not affect the performance.

The PTFE slip ring of the combined seal is easily damaged by drop shock or external hard force, so please be careful when using it.

2. Storage period of seals

The storage period of seals is shown in the table below.

The standard for the period of storage and storage is as follows.

|

product |

Material |

storage time |

|

Rubber monomer products |

Polyurethane (PUR) |

10 years |

|

Nitrile rubber (NBR) |

10 years |

|

|

Hydrogenated nitrile rubber (H-NBR) |

10 years |

|

|

Silicone Rubber (VMQ) |

20 years |

|

|

Fluorine rubber (FKM) |

20 years |

|

|

Rubber sintered products |

Nitrile rubber (NBR) |

10 years |

|

Fluorine rubber (FKM) |

10 years |

|

|

resin |

Polytetrafluoroethylene (PTFE) |

20 years |

|

Polyamide (PA) |

20 years |

|

|

Phenolic resin with cloth (—) |

20 years |

|

|

Polyester with resin fibers (88RS) |

20 years |

1. The storage period shown in the above table is to avoid direct sunlight, high temperature and high humidity in the warehouse, and use standard packaging.

It is premised on a seal that is stored in the installed state.

2. Since the rust (rust) of the metal part of the rubber sintered product is largely affected by the storage environment

It is excluded from the storage period.

3. When using the product for long-term storage, please confirm whether it is present or not.

The range of use, performance data and values described in this catalog can be used as a reference for the basic selection of seals, but in actual use, there may be cases where the general specifications are not applicable due to unknown factors and conditions. Therefore, please confirm the suitability of the product before actual use.