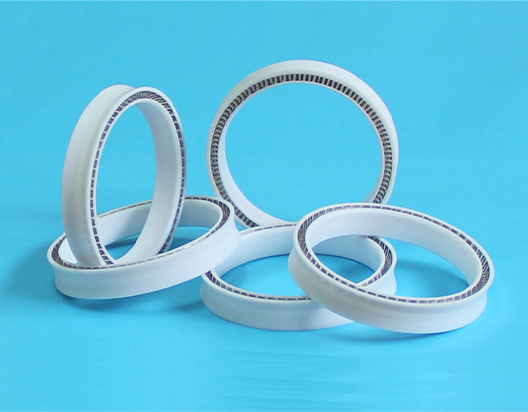

Pan plug seal

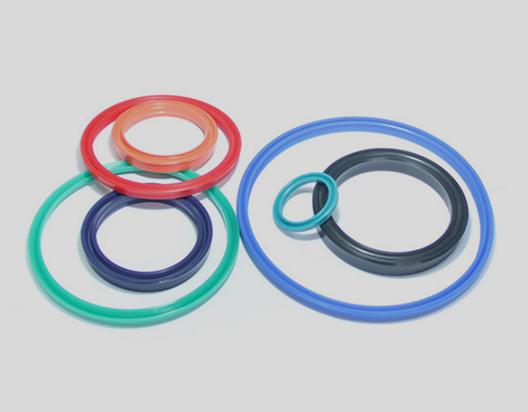

Related Products

Definition and characteristics of pan plug seal

Spring Seal/ spring energized seal/ Variseal is a U-shaped Teflon high-performance seal with a special spring inside. By the appropriate spring force plus the system fluid pressure, the sealing lip (surface) is pushed out. Gently press down on the metal surface being sealed to create a very good seal. The actuation effect of the spring can overcome the slight eccentricity of the metal mating surface and the wear of the sealing lip, while maintaining the expected sealing performance. Compared with other seals, it has the following characteristics:

◈The sealing performance is not affected by insufficient lubrication at start-up;

◈ Effectively reduce wear and friction resistance;

◈Through the combination of different sealing materials and springs, different sealing forces can be displayed to meet various application requirements. It is made by special CNC machining machine, and there is no mold cost-especially suitable for a small amount of various seals;

◈The chemical corrosion resistance and heat resistance are far superior to the commonly used seal rubbers, the dimensions are stable, and there is no deterioration of the sealing performance caused by volume expansion or shrinkage;

◈ Compact structure, can be installed in standard O-ring groove;

◈ Greatly improve the sealing ability and service life;

◈The groove of the seal can be filled with any anti-pollution material (such as silicone) - but not suitable for radiation environments;

◈ Because the sealing material is Teflon, it is very clean and will not pollute the process. The friction coefficient is extremely low, and it is very smooth even in extremely low-speed applications, and there is no "slip effect";

◈The starting friction resistance is small, even if the shutdown time is long or intermittent operation, the low starting power performance can be maintained.

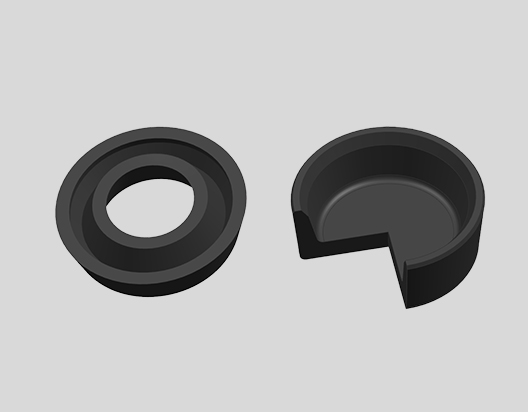

Pan plug sealing principle

The PTFE leaf spring combination U-shaped seal (pan plug seal) is combined with the appropriate spring tension and the system fluid pressure to push the sealing lip out and lightly press the sealed metal surface to form a very good sealing effect.

List of materials

|

name |

code |

main feature |

Operating temperature (℃) |

The main purpose |

|

Nitrile rubber |

NBR |

Excellent oil resistance, high wear resistance, good heat resistance and strong adhesion. The disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance and slightly lower elasticity. Nitrile rubber is mainly used in the manufacture of oil-resistant rubber products. |

Minimum temperature: -30℃ Maximum temperature: 100℃ |

Suitable for sealing of general hydraulic and pneumatic series |

|

Hydrogenated nitrile rubber |

HNBR |

It has good resistance to media, heat and oxidative degradation. The heat resistance is between FKM and NBR, and the wear resistance is also better than NBR. |

Minimum temperature: -30℃ Maximum temperature: 150℃ |

It is suitable for sealing of high temperature, chemicals and heat resistant hydraulic oil, and is widely used in metallurgy, electric power and other industries. |

|

fluororubber |

FKM |

Heat resistance, acid and alkali resistance and other chemicals: oil resistance (including phosphate ester series hydraulic oil) is suitable for all lubricating oil, gasoline, hydraulic oil and synthetic oil. |

Minimum temperature: -20℃ Maximum temperature: 230℃ |

It is suitable for sealing of high temperature resistance, chemicals and fire-resistant hydraulic oil, and is widely used in metallurgy, electric power and other industries. |

|

Silicone Rubber |

PMQ or VMQ |

Good heat and cold resistance, small compression set, but low mechanical strength. |

Minimum temperature: -60℃ Maximum temperature: 200℃ |

Suitable for high-speed and low-friction rotary seals and food mechanical seals at high and low temperatures. |

|

Ethylene propylene rubber |

EPM or EPDM |

Good weather resistance, aging resistance in air, general oil resistance, Freon resistance and various refrigerants |

Minimum temperature: -50℃ Maximum temperature: 150℃ |

It is suitable for various automobile oil seals and various gearboxes and gearboxes, and can withstand medium and high temperature. |

|

Teflon |

PTFE |

Good chemical stability, good heat resistance, good cold resistance, oil, water, steam, chemicals and other media. High mechanical strength, high pressure resistance, good wear resistance, low friction coefficient and excellent self-lubrication. |

Minimum temperature: -200℃ Maximum temperature: 260℃ |

It is used for sealing of construction machinery and high-pressure systems. |

|

Polyurethane |

PU |

Good mechanical properties, excellent wear and oil resistance, limited working environment temperature |

Minimum temperature: -35℃ Maximum temperature: 120℃ |

Used in refrigerators and refrigeration machinery to seal |

|

Acrylate rubber |

AEM |

Good heat resistance, oil resistance, in containing The lubricating oil with sulfur, phosphorus and chlorine additives has stable performance, aging resistance, oxygen and ozone resistance, UV resistance, excellent air tightness, The function of bending deformation. |

lowest temperature: - 25°C Maximum temperature: 150°C |

It is used to manufacture oil-resistant, heat-resistant and aging-resistant products, such as seals, hoses, chemical linings, etc. |