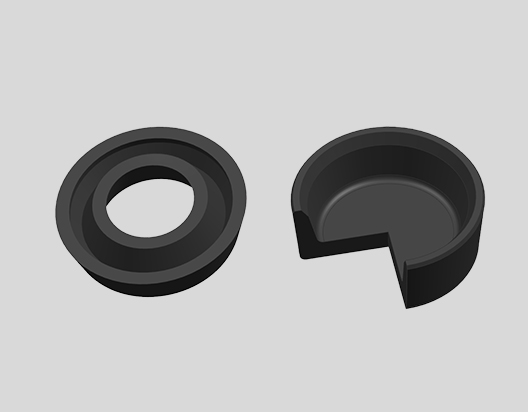

Y-ring

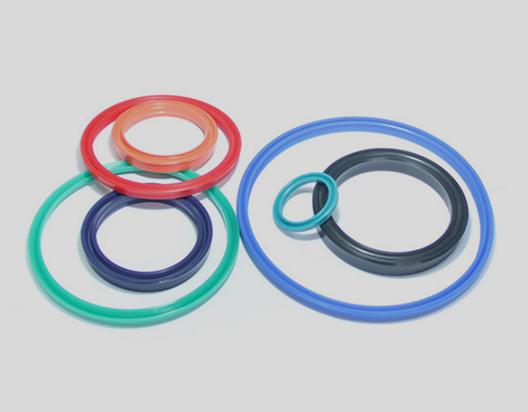

Related Products

Definition and characteristics of Y-ring

The cross-section of the Y-shaped sealing ring is Y-shaped and is a typical lip-shaped sealing ring. It is widely used in reciprocating sealing devices, and its service life is longer than that of O-rings. The applicable working pressure of the Y-shaped sealing ring is not more than 40MPa, and the working temperature is -30~80℃. Compared with other seals, it has the following characteristics:

◈Reliable sealing performance;

◈ Low frictional resistance and smooth movement;

◈Good pressure resistance, wide range of applicable pressures;

◈ Simple structure and low price;

◈ Easy installation;

Y-ring sealing principle

The Y-shaped sealing ring is attached to the coupling surface of the sealing pair by its open lip. When there is no internal pressure, only a small contact pressure is generated due to the deformation of the lip tip. In the case of sealing, there is a normal pressure equal to the medium pressure at each point in contact with the sealing medium, so the bottom of the lip ring will be compressed axially, the lip will be compressed circumferentially, and the contact with the sealing surface will become wider, At the same time, the contact stress increases. When the internal pressure rises again, the distribution form and size of the contact pressure are further changed, and the lip and the sealing surface cooperate more closely, so the sealing performance is better, which is the "self-sealing effect" of the Y-ring. Due to this self-sealing effect, a Y-ring can effectively seal the high pressure of 32MPa.

Y-ring material list

|

name |

code |

main feature |

Operating temperature (℃) |

The main purpose |

|

Nitrile rubber |

NBR |

Excellent oil resistance, high wear resistance, good heat resistance and strong adhesion. The disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance and slightly lower elasticity. Nitrile rubber is mainly used in the manufacture of oil-resistant rubber products. |

Minimum temperature: -30℃ Maximum temperature: 100℃ |

Suitable for sealing of general hydraulic and pneumatic series |

|

Hydrogenated nitrile rubber |

HNBR |

It has good resistance to media, heat and oxidative degradation. The heat resistance is between FKM and NBR, and the wear resistance is also better than NBR. |

Minimum temperature: -30℃ Maximum temperature: 150℃ |

It is suitable for sealing of high temperature, chemicals and heat resistant hydraulic oil, and is widely used in metallurgy, electric power and other industries. |

|

fluororubber |

FKM |

Heat resistance, acid and alkali resistance and other chemicals: oil resistance (including phosphate ester series hydraulic oil) is suitable for all lubricating oil, gasoline, hydraulic oil and synthetic oil. |

Minimum temperature: -20℃ Maximum temperature: 230℃ |

It is suitable for sealing of high temperature resistance, chemicals and fire-resistant hydraulic oil, and is widely used in metallurgy, electric power and other industries. |

|

Silicone Rubber |

PMQ or VMQ |

Good heat and cold resistance, small compression set, but low mechanical strength. |

Minimum temperature: -60℃ Maximum temperature: 200℃ |

Suitable for high-speed and low-friction rotary seals and food mechanical seals at high and low temperatures. |

|

Ethylene propylene rubber |

EPM or EPDM |

Good weather resistance, aging resistance in air, general oil resistance, Freon resistance and various refrigerants |

Minimum temperature: -50℃ Maximum temperature: 150℃ |

It is suitable for various automobile oil seals and various gearboxes and gearboxes, and can withstand medium and high temperature. |

|

Teflon |

PTFE |

Good chemical stability, good heat resistance, good cold resistance, oil, water, steam, chemicals and other media. High mechanical strength, high pressure resistance, good wear resistance, low friction coefficient and excellent self-lubrication. |

Minimum temperature: -200℃ Maximum temperature: 260℃ |

It is used for sealing of construction machinery and high-pressure systems. |

|

Polyurethane |

PU |

Good mechanical properties, excellent wear and oil resistance, limited working environment temperature |

Minimum temperature: -35℃ Maximum temperature: 120℃ |

Used in refrigerators and refrigeration machinery to seal |

|

Acrylate rubber |

AEM |

Good heat resistance, oil resistance, in containing The lubricating oil with sulfur, phosphorus and chlorine additives has stable performance, aging resistance, oxygen and ozone resistance, UV resistance, excellent air tightness, The function of bending deformation. |

lowest temperature: - 25°C Maximum temperature: 150°C |

It is used to manufacture oil-resistant, heat-resistant and aging-resistant products, such as seals, hoses, chemical linings, etc. |